Views: 0 Author: zcy Publish Time: 2025-08-29 Origin: Site

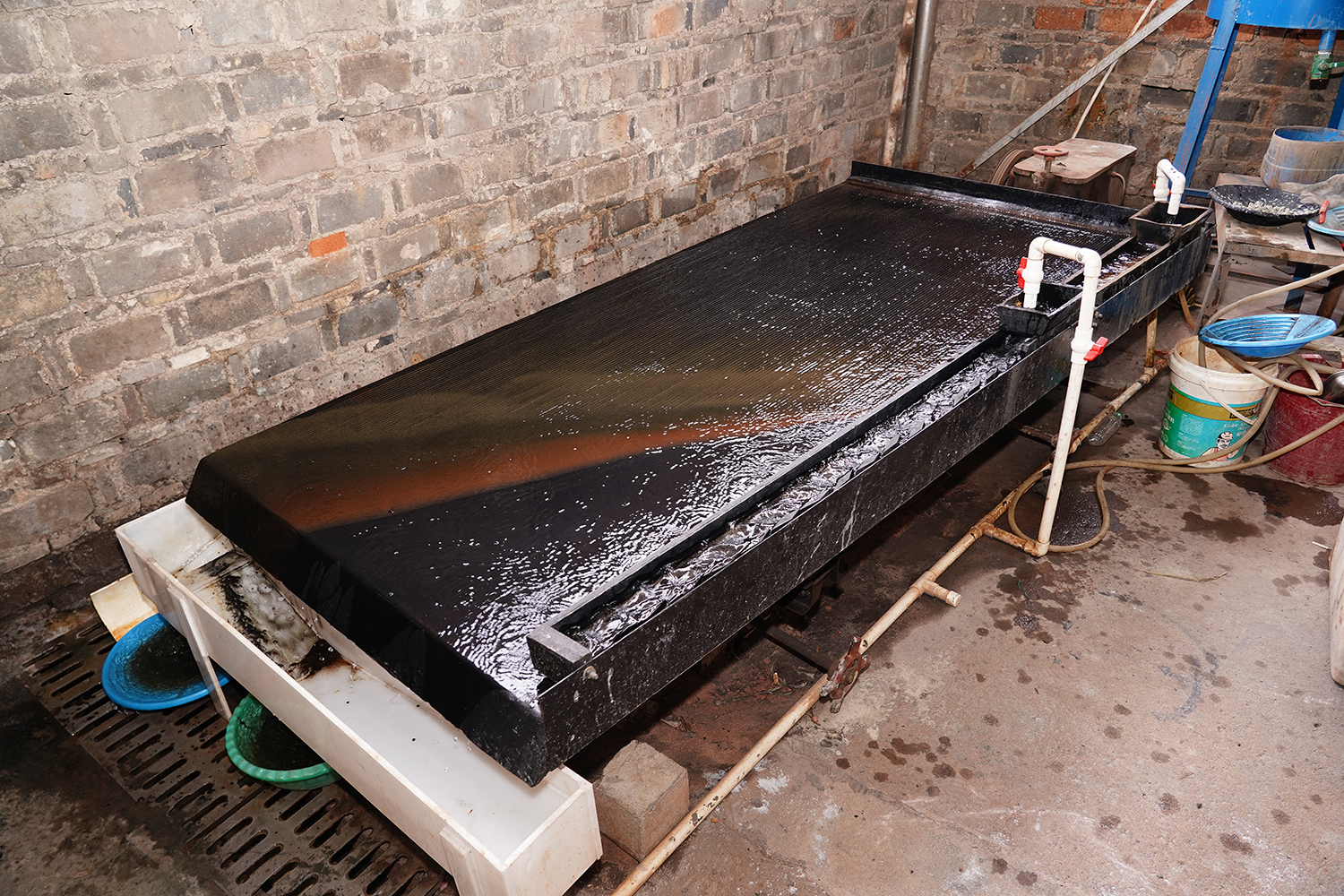

The 6-S mineral processing shaking table has relatively stable working performance during daily operations and is one of the key pieces of equipment in the mineral processing production process. However, in actual production scenarios, frequent conventional failures of the equipment are easily caused due to two core factors: firstly, the lack of scientific and standardized operating methods for daily maintenance leads to unaddressed and undiscovered equipment hazards; secondly, issues such as insufficient installation accuracy and non-standard procedures during component replacement directly affect the quality of equipment assembly.Moreover, it is critical that most frontline operators and maintenance personnel lack systematic fault detection capabilities and professional repair experience. When faced with equipment failures, they often cannot quickly locate problems or efficiently carry out repairs, which not only results in prolonged equipment downtime but also disrupts the normal production rhythm of the plant, ultimately causing unnecessary capacity loss and economic waste, significantly restricting the continuity and stability of mineral processing production.

I. Main Areas Prone to Abnormal Noises on the 6-S Shaking

During the operation of the 6-S shaking table, abnormal noises usually stem from wear, looseness, or assembly deviation of key drive, support, and cushioning components. The main vulnerable parts and causes are as follows:

Drive system

Large pulley: Abnormal noise due to groove wear or hub looseness.

Eccentric shaft: Impact noise from oversized bearing clearance or shaft neck wear.

Movement support components

Shaking rod: Motion noise caused by rod deformation or connecting pin wear.

Elbow plate: High-frequency noise from cracks or contact surface wear.

Cushioning & fixing components

Shaking rod spring: Periodic vibration noise due to fatigue deformation, insufficient elasticity, or loose ends.

Bed support components

Saddle base foot: Shaking noise if not fixed firmly to the ground or worn at the bed connection.

Bed structure components

Shaking box support plate: Structural collision noise from cracked welds or loose connection to the main box.

II. Inspection Methods and Troubleshooting for 6-S Ore Dressing Shaking Table

Prior to inspection, ensure safety precautions (e.g., power-off, wearing protective gloves). Only the elbow plate requires inspection during operation; all other parts shall be inspected when the machine is stopped. Details are as follows:

Large Pulley

Inspection: After shutdown, rotate/push-pull the pulley. Loose installation is indicated by noticeable clearance.

Troubleshooting: Fill the keyway gap with a scrap hacksaw blade/thin iron sheet, tighten the fixing screws, and recheck to confirm clearance elimination.

Shaking Rod

Inspection: Remove the two elbow plates first. Hold the large pulley steady with one hand and swing the shaking rod with the other. Normal condition: only difficult left-right swing (no front-back movement). Front-back movement indicates loose fixing.

Troubleshooting: Tighten the fixing screws on the shaking rod diagonally with a torque wrench, recheck, and reinstall the elbow plates.

Shaking Rod Spring

Inspection: After shutdown, check if the spring is skewed/eccentric. Uneven elasticity when pressed indicates misalignment.

Troubleshooting: Straighten the spring by tapping it gently with a hammer wrapped in soft cloth. For severe misalignment, loosen the fixing clips, adjust to the correct position, recheck verticality, and test-run.

Eccentric Shaft

Inspection: After shutdown, hold the large pulley steady with both hands and push-pull it front-back. Shaft looseness is indicated by noticeable movement/clearance.

Troubleshooting: Tighten the two hexagon socket screws on the oil seal cover of the 6-S transmission box, and recheck to confirm clearance elimination.

Elbow Plate (Inspect During Operation, Prioritize Safety)

Inspection: Run the machine at low speed, touch the two elbow plates with the thumb and middle finger (avoid moving parts). Vibration/clearance indicates improper fit.

Troubleshooting: Stop the machine, adjust the screws on the spring lead screw — tighten clockwise for excessive clearance, loosen counterclockwise for over-tightening — then test-run and recheck.

Support Plates on Saddle Base

Inspection: After shutdown, check if the 4 support plates are centered on the shaking box and if they scrape the box wall. Use a ruler to verify symmetry (allowable error ≤2mm).

Troubleshooting: Loosen the screws, adjust the plates to the center. For scraping, grind the plate edges or reposition (leave 1-2mm clearance), tighten screws, and test to confirm no jamming.

| | 703-3, Building F02, Phase Iii, Software Park, Jimei District, Xiamen City, Xiamen, Fujian, China |

| | +86-177-7076-6090 |

| | SalesHuang@xmzhiyanfuture.com |